Quick Tech: A Basic Guide to Engine Paint

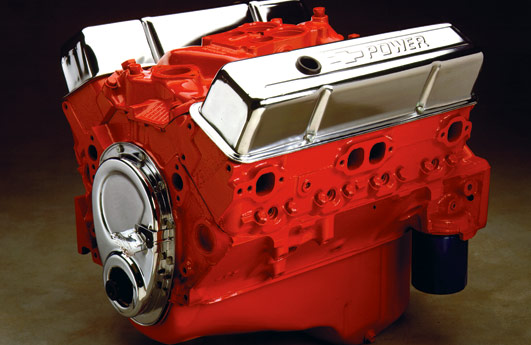

It takes a special kind of paint to survive under your hood.

Engine paint must withstand extremely high temperatures and be able to resist gasoline, oils, and other chemicals. And it has to look good, too—especially if the engine bay serves as a focal point for your hot rod or show vehicle.

Fortunately, companies like Dupli-Color, VHT, and POR-15 make paints specially formulated for engines. So what makes for a good engine paint? We asked the experts at Dupli-Color/VHT what to look for in a good engine paint and hit them up for some application advice to ensure the right finish. According to Mark Eichelberger, Associate Product Manager at Dupli-Color/VHT/Tri-Flow, a good engine paint should have three characteristics: heat resistance, gloss retention, and resistance to chipping and flaking.

Fortunately, companies like Dupli-Color, VHT, and POR-15 make paints specially formulated for engines. So what makes for a good engine paint? We asked the experts at Dupli-Color/VHT what to look for in a good engine paint and hit them up for some application advice to ensure the right finish. According to Mark Eichelberger, Associate Product Manager at Dupli-Color/VHT/Tri-Flow, a good engine paint should have three characteristics: heat resistance, gloss retention, and resistance to chipping and flaking.

That’s why engine paint is typically an enamel paint.

Enamel paints typically offer a hard, glossy finish and have excellent color retention. In addition, enamel can provide superior heat resistance—a must for automotive engine use. Because under hood temperatures generally run between 250 and 300 degrees, a good engine paint is usually rated to handle temperatures up to 500 degrees—and beyond. You’ll also find that some companies, such as Dupli-Color, add ceramic resins to its engine paint for added heat dissipation. Ceramic is proven to be extremely effective in high temperature paints for headers and exhaust systems and can even be applied to jet engines.

When properly cured, enamel paints not only offer excellent chip resistance, they also resist rust and corrosion. They are also fairly simple to apply—either by brush, roller, or spray, depending on the paint—making them easy to work with even when your engine is still inside the engine bay. The most common engine paints are sprays and often involve simple “rattle-can” aerosol cans.

Last but not least, enamels can be formulated in a wide range of colors, allowing manufacturers to offer a huge array of options. In many cases, this includes factory-matched colors like Chevrolet Orange, Ford Blue, and Cummins Beige. Like any paint, the final look of your engine paint comes down to proper application—and a bit of patience.

Application Tips

- Sand the engine thoroughly. You can use a wire brush to help remove old paint and debris.

- Clean the block with a grease and wax remover prior to painting to remove oils and other chemicals.

- Wipe down the engine to remove loose particles or use an air hose to clean debris.

- Start with a high-heat engine enamel primer for maximum corrosion resistance and uniformity of your top coat color.

- Apply primer and top coat engine enamel color with a light “tack” color first to avoid runs and sags.

- With spray applications, use a long, sweeping motion to apply the paint evenly and without runs.

- Continue to apply two more light coats followed by a medium wet coat for the best coverage and smoothness of the paint finish. As a general rule of thumb, a few thinner coats will provide a higher-quality finish than one or two heavy coats.

- For extra protection, use a high heat engine enamel clear coat applied the same way as the primer and top coat engine enamel color.

- As always with paint, make sure to wear a mask or apply in a well-ventilated area.

Regarding VHT Hi Temperature Engine Enamel: Can I apply the SP148 primer & color top coat both within the same hour of the primer application? Must I wait 7 days for the primer to dry, before applying the color coat? Must I then wait a further 7 days to apply the clear coat. Or do I have to wait 7 days for the primer to cure before heat treating the primer to fully cure before applying the color coat, after which, do I also wait 7 days for it to cure before heat treating it to fully cure? And if I then apply a clear coast, likewise do I have to wait 7 days before the color coat cures to then fully cure by ‘baking’ it for 1 hour at 93 deg. C.? If so, that’s 21 days before I can handle this VHT Hi Temp Engine Enamel painted object without it chipping with normal handling.

I have had virtually zero resistance to chipping, despite rigorous care in surface preparation before I applied just the color coat & baked it. This was partly due to improper on-can instructions, mentioning the necessity of primer after, after the fact & the almost imperceptible, tiny 3 point font in which it was printed. Applying the color coat without the primer is a waste of time, effort & money. However, some have reported that even with primer, the VHT Hi Temp Engine Enamel is not chip resistant & comes off easily. Just tell me straight please if you would be so kind. What are your best suggestions please?

Peter Greening

Sydney, Australia

My Apologies for the above rant. However, I had just spent hours preparing various nuts, bolt & washers for the barrel & cylinder head for a vintage motorcycle restoration project. I asked an auto shop guy about VHT paint & no mention of the need to use the primer was forthcoming. I then read the can, rather attempted to read the very fine print, in which the instructions were written/ hidden. I got up to the part about shaken the can & spraying & got straight into the job. However, in the next sentence which I didn’t notice until after the fact, was the bit about primer. So, I finish the job, wait 7days, bake it to fully cure & place the parts in a plastic bag only to find that the slightest contact had chipped the paint & so I was annoyed at this. Hence the preceding rant. I have since calmed down & discovered that after purchasing a can of primer SP148 that it has far easier to read & clearer instructions. So, here’s hoping my second attempt, this time using applying the primer & a clear top coat will yield better results.