Losing Your Cool: 9 Cooling System Myths and Mistakes — and Why to Avoid Them!

There are many myths and misconceptions about engine cooling, but the truth is your engine’s cooling system must perform a balancing act. It needs to extract enough heat to keep your engine happy, yet maintain enough heat to keep it operating efficiently. That means keeping the engine in the 180- to 210-degree F range.

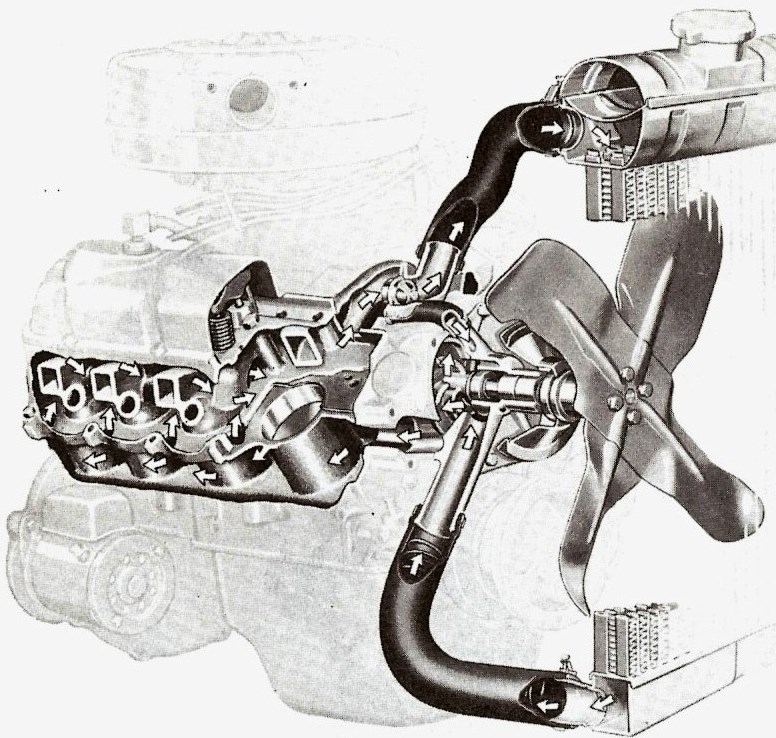

To achieve and maintain optimum temperature range, a good cooling system needs the right-sized radiator and fan combo. It must also have the appropriate water pump speed and coolant flow between the engine and radiator.

Typically, when engines overheat or run too cool, it’s because of these cooling systems myths and misconceptions. Here are some of the more common myths and mistakes and why you should avoid them.

Eliminating the Thermostat

One of the greatest — or perhaps worst — cooling system myths is that you can remove your thermostat to eliminate overheating. This will only add insult to injury! When coolant never has a chance to give up heat via the radiator, it gets hotter and hotter, especially if you’re stuck in traffic. And even on the open road, coolant never has a chance to park in the radiator long enough to give up heat energy to the atmosphere.

Never operate your engine without a thermostat!

Thermostat selection boils down to application. Although enthusiasts tend to choose a 160-degree F thermostat to treat overheating issues, the 160-degree thermostat was originally intended for alcohol antifreeze back in the day. The best thermostat for classic vehicle applications today is the 180-degree thermostat. If you’re experiencing overheating with a 180, you have deeper problems with other components. Late-model computer-controlled vehicles mandate the use of a 192- to 195-degree F thermostat.

Water is the Best Coolant

Another myth is that water is the best coolant.

This is true in terms of heat conduction; however, it is also the best source of corrosion. If you are using straight water, you should always add water pump lubricant and a corrosion inhibitor. Also, use a coolant enhancer like Water Wetter, which improves surface tension and heat conductivity.

Coolant manufacturers often suggest a 50/50 mix of ethylene glycol and water, which will protect your cooling system down to -34F. If you’re expecting temperatures colder than that, you need a block heater or a warm garage. Mark Jeffrey of Trans Am Racing in Southern California tells us he runs 100-percent ethylene glycol and no water without consequence and has been doing it for many years. His logic is coolant temperature runs only marginally higher and this approach eliminates any risk of corrosion.

If you opt for the 50/50 mix, you can buy antifreeze already mixed with water for the sake of convenience. If you’re going to run an ethylene glycol and water mix, it is suggested you run distilled water to keep minerals out of your cooling system.

Summit Racing offers you another coolant option known as Evans High Performance waterless coolant. This is the last coolant you will ever have to buy because it is permanent. You run 100-percent of it in your vehicle’s cooling system. Begin your Evans regiment with new hoses and cooling system components and a system that is bone dry. If you’re servicing a system with traces of ethylene glycol and water, the Evans Coolant Conversion Kit is the best way to get started.

Improper Coolant Filling

We’ve seen a lot of people either under-service or over-service coolant.

When you are servicing a cold engine, you should add coolant to one inch below the filler neck which allows for expansion as the engine warms. Coolant can rise as much as one inch as the engine warms up. Start your engine with the radiator cap removed and coolant one inch below the neck. Then, observe as the engine warms. Allow time for the thermostat to open and for the engine to burp any stray air pockets.

No Anti-Collapse Spring

There are those, including hose manufacturers, who believe you don’t need an anti-collapse spring in the lower radiator hose. The truth is, you must have an anti-collapse spring in the lower radiator hose if you have an older vehicle with a conventional cooling system.

Because the lower radiator hose channels coolant to the water pump and engine, it is susceptible to negative pressure and collapse at high rpm. The anti-collapse spring prevents that from happening. One hose manufacturer says you don’t need the anti-collapse spring because it was used only for factory-fill purposes. This has never been true because of the positive pressure on the lower hose during fill.

Always run an anti-collapse spring in the lower radiator hose.

A Faster Fan is a Better Fan

There are many myths regarding electric fans. One belief is the faster a fan turns, the better — which is not completely true. At high speed, the radiator slipstream should be strong enough to carry heat from the radiator. When air is moving too fast, you get into boundary layer issues where heat doesn’t get carried away because air isn’t actually touching fins and tubes.

You want air to move slowly enough across fins and tubes to where it carries heat away. At speeds above 40 miles per hour your engine doesn’t need a cooling fan. This is why a thermostatic clutch fan or electric fan works best.

More Fans are Better

Some folks believe more fans are better. But that isn’t completely true, either. You don’t really need a fan both behind and in front of the radiator. Ideally, you will have a fan behind the radiator that provides cooling capacity based on coolant temperature. If your vehicle needs two cooling fans, there’s a deeper problem than fan capacity.

Improper Fan Spacing and Shrouding

One rule we see broken time and time again is fan spacing and shrouding. In most cases, cooling fans should be shrouded for proper vectoring of air velocity through the radiator. We recommend you pay close attention to what the factory does in any application.

Overlooking the Radiator Cap

Aftermarket radiators are popular upgrades, but you should also pay attention to your radiator cap.

Your coolant is under pressure to keep the boiling point as high as possible. That’s why you you want the highest pressure cap rating suitable for your application. Caps for older vehicles should be rated for 7-12 pounds; newer vehicles should have radiator caps rated to 12-18 pounds.

Cheap is Cool

It’s cliché, but you get what you pay for. When replacing cooling system components such as hoses, the water pump, and thermostat, don’t do it on the cheap. Spend good money on the best components and sleep better. Goodyear Super Hi-Miler cooling system hoses last longer than your average off-the-shelf hose, especially when paired with high-quality worm gear clamps.

You can find a wide variety of water pumps for nearly every application imaginable. Regardless of what brand of pump you choose, always opt for a high-flow water pump and be mindful of pulley ratio (pump speed).

Now that you know what pitfalls to avoid, scroll through the slideshow below for some valuable tips on choosing cooling system components.

[portfolio_slideshow id=55509]

Opening a myth’s story with a myth? The thermostat does one thing and one thing only. It regulates the MINIMUM water temperature. The “slowing down the coolant” myth is a leftover from the Flathead Ford days when it was necessary to force coolant to flow at the rear of the motor. While it is important to use the proper thermostat to ensure that the engine reaches proper operating temperature for more efficient combustion and lubrication, the elimination of the thermostat, in itself, not only will not but, by the laws of fluid thermodynamics in a closed system, CAN NOT cause overheating. What it WILL do is reduce the temperature differential between the hottest and coldest points in the system. With my regards to the esteemed Mr. Smart and the myriad of folks who will swear on a stack of Bibles that this has happened to them I shall now don my “flame suit” and return to my laboratory.

Amen. I was just about to correct them also and saw your comment first. Unbelievable they posted an article specifically to bust myths and actually included two. Their other point that is incorrect is their belief that slower air past radiator fins cools better than fast air. Where do they find this crap?

Slower air DOES cool better. Heat transfer takes time. There’s a reason a single combustion cycle in an engine is considered adiabatic; there isn’t time for it not to be.

Faster air causes turbulence as you pass the Reynolds number of about 10000, depending on the application. A turbulent boundary layer means worse cooling. Period. There’s a reason all the manufacturers shut off their fans at high speed now. You’re TRYING to keep it laminar as often as possible.

dear kyle , are you sure that laminar flow intercange is better than turbulent flow? who say you this? more speed = more air/time = more heat exchage/time = low final air temp that no mean less heat exchange , in high Reynold numbers better inter change , in laminar flow the temp in layer near the surface is similar to the temp of surfe , that mean the gradient is small that mean the exchage is more slow.

I hope its was legible , sorry for my english

Dear Kyle, because you blow the soup when it’s hot, with this it is increasing the REYNOLDS NUMBER, AND IT WOULD COOLER SLOWLY.

Although this example is far from aerospace engineering. But I think it is didactic

3 pieces of misinformation here:

1. The idea that removing the thermostat causes the coolant to move so fast that the heat can’t be disappated because the water isn’t in the radiator long enough?

One only needs to look at the engine side to expose this nonsense, if the water is going too fast for heat transfer, it’s not going to be able to extract any heat from the engine either with the result the water would stay cool and the engine heating up into a red hot block……..Doesn’t happen!

The faster the water moves through the system, the more heat can be transferred, that’s what the thermostat does, controls the rate of coolant flow. It does get to a point when no further increase in flow will create any further cooling rather than faster flow impeding cooling.

2. The same nonsense with the fan statement, faster air flow creates more cooling, always!

3. Water is not the best conductor of heat, it does however have one of the highest heat capacities of any fluid. Putting other coolants in systems that were originally designed for straight water(cars before 1970) requires either bigger radiators or increases in water pump speeds to create the same cooling when 50/50 mixes of water/glycol are used.

Good Lord. No.

As a general rule, ρAv=ρAV. So the significantly smaller tubes in the radiator mean significantly higher speed. There’s a reason the tubes are so long. It takes time to transfer heat. Similarly, metal to water isn’t the same as water to metal to air.

Faster air creates more cooling always? Go look at the Red hot space shuttle and try that statement again. Faster air creates more HEAT always. If you have shear, due to speed of the flow causing turbulence, you’ve lost heat transfer capacity. Period.

The third point is taken out of context. They say, specifically, that it’s the best COOLANT in terms of heat transfer. There are plenty of materials that have higher conductance, but they aren’t *coolants.* Especially not when used in the context of automotive engines.

ρAv=ρAV is just double talk. Surface area not constant flow rate is at issue.

Using the reentry of the space shuttle as an example of the reaction of air flow makes me wonder how much you understand what is going on. And yes, I studied physics. When a spacecraft reenters, very little heat is generated by friction (air passing by). Mostly what happens is, all the heat already in the air molecules piles up in front of the spacecraft leading edge. All air has a certain amount of heat in it, which is just another way of saying it has a certain amount of kinetic energy in all the air molecules wiggling around. Compress air quickly enough, and all the energy or heat gets concentrated in a smaller volume faster than it can radiate, conduct, or convect away. As a result, the air can get hot enough to glow caused by energy density not air flow.

If facts are of concern to you then note this chart. As the velocity of the car increases, air flow through the radiator increase is proportional. Note the increase in heat transfer performance. So in fact more air flow through a given radiator does not always mean more heat. In fact it means less. More heat is only formed when compression becomes a factor,otherwise known as the velocity boundary layer, then only when that overcomes the heat dissipation by volume.

https://www.maplesoft.com/support/help/content/1076/image591.png

The fact is, higher velocity will give you more heat dissipation until compression becomes a factor. The only other issue involved is the ability of the material to transfer kinetic energy. In simple terms, when air flow reaches the cores maximum ability to transfer heat, any increase is wasted.

What is not mentioned here is the fact that air flow across the engine surface also creates a cooling effect.

ρAv=ρAv isn’t double talk. At all. It literally means that at any cross section of a flow you take, that the total mass/time is constant. It’s LITERALLY one of the most important equations in fluid dynamics. Mass is conserved.

You trying to tell a literal NASA rocket scientist how space shuttles work is pretty well hilarious.

ALL drag is friction. You can’t “pile up” air in front of something if it has no friction.

Heat also isn’t synonymous with kinetic energy. At all.

Your claim that denser air means worse heat conduction is similarly hilarious.

More heat through a radiator ALWAYS increases the heating at the radiator. Compression isn’t the problem we’re talking about, it’s TURBULENCE. It’s about the Reynolds Number. Turbulent flow does NOT conduct heat the same as laminar flow.

We’re talking about a Fanno-Rayleigh flow.

The heat removed as the air crosses the engine’s surface is absolutely negligible.

Kyle, back to school for you.

You are completely confusing virtually unrelated scientific concepts, and applying them in some twisted fashion that does not resemble science.

Using the space shuttle re-entry as an example of why increasing turbulent airflow somehow increases heat at a heat exchanger, is absolutely awful.

First off,

During the

fastest/hottest part of the shuttle re-entry, a very energetic pressure wave develops at its leading

surfaces, and this energy density is enough to cause molecules

to dissociate, and ionize their atoms. It’s incandescent plasma.

Plasma largely doesn’t follow the

laws of conventional thermodynamics. The leading edges will experience extreme heating due to the pressure wave and electrostatic charging.

All of that has absolutely NOTHING to do with heat exchangers. Conventional thermodynamics apply, we are at conventional altitudes and conventional speeds. The faster and the more turbulent the air/water flow inside or outside an exchanger, the more exchange occurs. Period.

You are either a flat-out liar or have gotten very confused.

I’m an aerospace engineer. We’re uh… Pretty well trained with fluid dynamics.

You should try taking fluid dynamics past high school physics.

Your claim is that since heat cannot, if itself, pass from body to a hotter body, that elimination of the thermostat cannot mean overheating. Except the engine is ALWAYS hotter than the coolant. The entire idea is to distribute the heat throughout the cooling system, mainly the radiator, to *reduce heat in that system.* You WANT your engine as hot as possible.

The thermostat is an object in the flow. It will absolutely be a restriction. Thus slowing down the flow.

There’s a reason they hire us to design engines and cooling systems. It’s more in depth than Bernoulli.

I would like to call BS on the aerospace engineer thing, but who knows……. Not sure what rho*A*v = rho*A*V means.

When calculating heat transfer, the governing equation is Q=UAdT. Q is the rate of heat transfer (BTU/h or some other convenient units). U is the overall heat transfer coefficient (BTU/h*degF*ft2). A is the heat transfer surface area (ft2) and dT is the temperature difference between the two fluids on either side of the heat transfer tube.

U is made up of three components. There is the heat transfer coefficient from the fluid on the inside of the tube to the tube. The second is “resistance” to heat transfer through the metal tube wall. And the last is the heat transfer coefficient between the fluid outside the tube and the outside surface of the metal tube.

The resistance to heat transfer through the metal of the tube depends on the material of the tube (thermal conductance) and the thickness.

The heat transfer coefficient from either fluid to the metal surface is a function of fluid characteristics and velocity. Higher velocity results in higher heat transfer. This is primarily because there is higher turbulence at the tube surface, which constantly brings cooler (or hotter depending on which side of the tube) fluid into contact with the hotter (or cooler, depending again) metal surface.

Increasing the air velocity on the outside of the tube has a bigger effect than increasing the velocity of the water on the inside, because the heat transfer coefficient of water to metal surface is so much higher than air to metal surface.

Removing the thermostat will not make the water run hotter unless the pump begins cavitating, which is unlikely unless the pump is running at very high speed (for instance maybe in a race car engine). The other possibility is if the cooling system is a bypass system, which bypasses some coolant around the radiator when the car is warming up and the thermostat is closed. In this case removing the thermostat will result in constantly bypassing water around the radiator which will result in overheating. The rotary engines in Mazda RX7’s have this system.

This is how it works in systems like a car radiator. Heat transfer might be different with a space capsule, because of compressibility, supersonic flow and all that rocket stuff (which is as good as greek to me).

I have been designing heat exchangers in boilers for about 35 years now. I continue to have customers pay me to do this, so it seems that I have probably gotten this right a few times before.

Cheers,

Carl

You literally didn’t respond to any of my points. Utter illiteracy.

Carl is largely correct… except for the fact that removing a thermostat will decrease pressure in a system that needs pressure to help prevent DNB (Departure from Nucleatic boiling)… this basically means that nucleatic boiling (small bubbles on surface) is ok, but the moment it becomes film boiling, the steam creates an insulated surface of the block or head that is not in direct contact with the liquid coolant molecules any more. This film boiling also increases the chances of pump cavitation.

A thermostat’s role is to increase pressure, not actually to slow down flow.

Thank You for publishing this article. I’ve been buildings Engines for some 35+years,10 of which was in Daytona Beach;Florida.Being from New York[which was tough enough] I always believed in installing a 195 degree thermostat,not only for heating reasons but to maintain a complete balance across the whole Engine.Down south for some reason there convinced because they don’t need that much”Cabin Heat” you don’t need a thermostat.{These are the same People who refer to Engines as “Motors”}Every engine I’ve ever disassembled without a Thermostat was all “Gunked” up inside.Removal of a stuck closed thermostat along side the road is OK to get you where your going. I had myself a 440 Mopar with a stuck thermostat;in Florida no doubt, on I-4,,started over heating in traffic,, I pulled off to the shoulder,,Popped the stuck thermostat out,,,made a gasket,,,let it cool down for 45-60 minutes,filled it with water, got back on the road started cruising down the road,{traffic let up} and started it overheating,,4 Core Radiator,full of water,,,but the water was flowing to fast to allow the proper heat exchange for optimum cooling. So,YES a Thermostat is very important!

MotorHead~Ty

Ok. Maybe I can help with this one. How can it be that if you slow down the flow through the radiator, the engine will run cooler? Look at it this way, if you slow down the flow through the radiator, you also slow down the flow through the engine too. Therefore, the engine heats the water even more right? The 440 was an engine that could overheat in a heartbeat. I think they all had inadequate cooling systems,

Water to metal to air is not the same as metal to water

Use to install smaller size washers instead of thermostat in Stock Car, car never overheated, worked for me and the car, low cost repair.

Don’t forget air restrictions. If you are changing the grill and crowding the engine compartment in a resto-mod application, adding fans, headers and HP, any restrictions can cause big issues. All of the items above are important and each one will affect the temperature in one way or another. I put vintage air in my resto Mustang, and can watch the temp gauge climb the minute I turn the compressor on.

195 degree thermostats exist for emissions reasons only. What a lot of people forget is that if you actually want your car to run cooler you have to adjust the fan system/ecu to account for it. Otherwise, you’re just changing the initial temp the thermostat opens at, not the overall operating temp of the engine.

No. The thermostat controls how much of that cooled coolant comes back into the engine, it doesn’t matter if there are huge fans cooling down the radiator. The water inside the block controls the operating temp of the whole engine. True the oil in the sump will not be as hot, but in most situations this is not a consideration. There are extremes of this and certainly older trucks in cold climates run radiator blinds to keep the whole of the engine warmer.

No Cameron, the thermostat does not just “open” it regulates the temperature so it is constantly adjusting the flow rate to keep temperature constant once the engine warms up after initial startup.

“For car owners or those that are not really into cars car maintenance may sound daunting especially for high tech cars.

http://www.wrightimport.com/“

hmmm.

im not an engineer but i am not an idiot.

all the i formation here ia correct except one point. the advice to fill radiator to one inch below the brim then close it up and walk away is aimply incorrect, and also purely stupid. It doeant even deserve an explanation as to why. I just think this is an accidental missinterpretation between a closed pressurized system and an ezpansion tank system. I strongly suggest you rewrite that bit Jim. Inteoducing air into the pressurized cooling system is going to cause lots of damage around the world, as you post is now at the top of googles search result for coolant information and people will take it as gospel.

There is no problem with air in a pressurized system such as this. What do you think happens as your coolant gets low? I have run with a leaking water pump for 6 months now and am often down a gallon of fluid and just top it up every so often without problem. ( I did finally get the pump fixed this week)

Enough to give a guy a headache…

I have 30+ years working on cars in Phx 4 years of which was in a radiator shop..

IF there was ever a place to test any of this, that would be the place (could be why several manufacturers choose to have proving grounds there…

My observation is both sides are right.. It is my guess that it all goes back to how the system is engineered.. How well are the parts matched in the first place.. I have seen cars (BBC) overheat without thermostats and as soon as a restriction is added, they start running cooler.. On my 98 chevy truck with a small block, it simply wont heat up….

My guess? Some systems are more balanced than others.. Yank a tstat out of a car that has an internal bypass port..

The real talent? figuring out why a car is getting hot and fix it.. Certainly can not match theory with a group of engineers that never worked in the field.. Sometimes you don’t know what you don’t know..

“Mark Jeffrey of Trans Am Racing in Southern California tells us he runs 100-percent ethylene glycol and no water without consequence and has been doing it for many years. His logic is coolant temperature runs only marginally higher and this approach eliminates any risk of corrosion.”

That might work in California, but “100-percent” ethylene glycol will freeze at about +20 degrees F. It sounds odd but it is the addition or mixing with water that depresses the freeze point of glycol antifreeze to -34 degrees F below zero. By itself, not so much.

This is really bad advice for anyone who lives where it gets cold, which is most of the country and Canada.

Something that explains slower coolant flow better. Keep in mind that your desire is net heat removal from engine. Slower coolant flow does absorb more heat and exit engine hotter. But that hotter coolant sheds heat much faster in the radiator due to the higher temperature differential with the outside air. So your net result is higher heat removal. Sounds weird but that’s one of the pieces of heat exchanger engineering/design.

Removing a thermostat from the cooling system can cause higher engine temperatures due to a not so obvious behavior. Gases are a poor conductor of heat. For there to be low thermal resistance between the cylinder head coolant passages and the coolant, the coolant must stay in a liquid state. If the coolant changes to a gaseous state, the thermal resistance goes up massively.

If you model the pressure drops around the cooling system in a loop, using the fluid dynamics equivalent of Kirchhoff’s Voltage Law, you will find that removal of the thermostat results in a much lower average pressure in the cylinder head coolant passages. This allows the coolant in the cylinder head to boil. Once the coolant is in a gaseous state, very little heat transfer occurs.

This is why some racers install flow restrictors in place of the thermostat. It creates the required pressure drop, to keep the fluid behind it at a high pressure. I learned about this requirement from an OEM engineer who measures engine behavior with 20+ coolant temp and pressure sensors installed throughout the cooling system. In 30 years of automotive work, that was the only person I’ve ever run across that could explain this behavior.

There were some interesting ideas presented. Personally, I generally trust the experts, and there are some differences between modern designs and the pre-FI engine.

Yes, the thermostat is in place to regulate water flow, and allow the engine to reach its proper (minimal) operating temp. With it removed, engine temps run lower and you computer thinks it needs to keep a richer fuel mix than otherwise necessary.

Small/thinner radiator tubes allows heat to conduct quicker, and allows room for additional tubes. To protect these delicate radiators, modern cars often have sealed systems. Little/no air is introduced when flushing these systems with the proper equipment. Your coolant will also last longer. With heavier cooling needs, the manufacturer adds additional cooling surface.

Water is the best fluid for cooling an engine… but not the best fluid for long-life health in your family auto.

At freeway speeds, you engine does not require a fan. Manufacturers moved to electrics to eliminate the power consuming engine-mounted fan and belt. The shroud can also be closer to the blades, which improved efficiency.

http://www.saldanaracingproducts.com/Cooling%20System%20Principles.pdf

Water is a better coolant than any antifreeze and if you are racing it is the proper liquid to use. If you blow a head gasket while using water it does not necessarily kill the bearings and crank, antifreeze will. As far as coolant speed, coolant needs to periodically almost stop flow in a street car to give the radiator time to do its work, not because coolant flowing faster doesn’t remove more heat but because the radiator cannot keep up. In some situations you can flow air too fast and cause a boundary layer that hurts cooling, but, in the case of a street car it is much more likely you are just losing efficiency and wasting power. Also, in a lot of cases in muscle cars or older hot rods your biggest enemy is a high pressure area in the engine compartment that holds the heat instead of allowing it to exit under the car. Mostly it seems to me you have to address these problems as a system, one system, and if you do that you will find each of you have a good handle on one piece.

the thermostat may not only open the top hose. it may shut off the bypass. if you remove the thermostat, water can short circuit the radiator.

Unfortunately this article is itself falling prey to a myth…

“…coolant never has a chance to park in the radiator long enough to give up heat energy to the atmosphere.”

Ouch.

The heat transfer inside the rad occurs actually very quickly… the faster and the more turbulent the water flow, the more heat is exchanged. The slower and the more laminar the flow, the less overall heat is removed from the system.

Just a few points to add to the conversation. What we experience can be explained by heat transfer.

Firstly, most automotive water pumps are centrifugal pumps (https://en.m.wikipedia.org/wiki/Centrifugal_pump). When a centrifugal pump operates on the right side of its curve ( pressure developed vs flow rate – http://resizeme.club/picresize-230_19.html) it will cavitate. Decreasing the outlet pressure of the pump will drive the pump to operate on the right side of the curve and, if the pressure is sufficiently low, it will cavitate. This can happen when the thermostat is removed depending on how the system is designed (i..e., bypass system design, pressure drop through the system with/without a thermostat, radiator size, coolant flow rate, etc). When a pump cavitates, it will not be able to pump as much water as it did when it had more restrictions in the outlet (operating more to the left side of the curve). This lower water flow will reduce the heat transfer in the engine and radiator. Also, the higher pump suction due to operating the pump at a higher flow rate could collapse the water pump inlet hose if it does not have a system to prevent the hose from collapsing. As an aside – for industrial centrifugal pumps, lower outlet pressures could make it operate outside its best operating point leading to premature seal/bearing failure.

Secondly, unless you are traveling very slowly, the air flow through a radiator is turbulent (which promotes better heat transfer).

Lastly, the more water flow through your engine can increase heat transfer, to a point. Cooling is a function of the change in water temperature multiplied by the flow of the water multiplied by the specific heat of the fluid: http://hyperphysics.phy-astr.gsu.edu/hbase/thermo/spht.html. It is just not the increase in water temperature that drives the amount of energy removed.

Each vehicle is somewhat different and we may not be able to apply what works for one car to another car that is designed differently, but the physics/engineering principles do apply to all vehicles. The real difficulty is finding the root cause of the problem.