Quick Tech: How to Read a Vacuum Gauge to Pinpoint Engine Problems

A vacuum gauge is an invaluable resource for tracking down engine issues.

The key is understanding what your gauge is trying to tell you. We’ve put together this quick-guide to reading your vacuum gauge to help you identify potential mechanical or tuning issues more quickly. We’ve seen this topic covered before, but it’s information worth repeating, keeping—and even bookmarking.

To get started you’ll need to hook your vacuum gauge to an intake manifold vacuum source. You can hook a tee-fitting into an existing vacuum source or pull a line, such as one that leads to your transmission. Check to make sure all vacuum hoses are connected and not leaking.

Once you’re engine is up to operating temperature, you can begin reading your vacuum gauge. Below are some of the most common readings and diagnoses you’ll find:

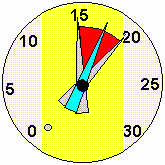

Normal

This a normal reading—between 17 and 22 inches of mercury. Keep in mind, this reading is ideal for stock-cammed engines running at sea level. Higher elevations may cause slightly lower readings. For every 1,000 feet above sea level, you can expect the reading to be about one inch lower. You can also expect the readings to be lower for more aggressive cams.

Steady Low/Extremely Low

The gauge at left shows an extremely low reading, which holds fairly steady. This means the engine is producing less power and, therefore, less vacuum. Common causes of steady low reading are blowby due to worn piston rings or possibly late ignition or valve timing. An extremely low reading could also indicate an air leak at the intake manifold or throttle body.

Steady Low/High Swing

A regular swing between high and low readings often means a blown head gasket between two, side-by-side cylinders. To confirm, you’ll need to perform a compression test.

Rapid Vibration at Idle

If the needle vibrates rapidly between 14 and 20 inches of mercury, but then steadies as rpm increases, you may be dealing with worn valve guides. How fast the needle vibrates is telling of how many valve guides may be worn.

Fluctuation Under Acceleration

Conversely, if the gauge’s needle swings back and forth as the engine accelerates, your valve springs are probably too week for your engine. The swing on the gauge is usually anywhere from 10 to 22 inches of mercury, depending on the speed of the engine.

Drastic Needle Drop

With exhaust restriction, the vacuum gauge will often start in the normal range but will soon drop drastically as rpm is increased. You likely have a restriction somewhere within your exhaust system or a damage exhaust component.

Abnormally High Reading

Conversely, a choked or restricted air cleaner would result in a higher than normal reading, depending on how hard the engine works to pull in air.

Normal/Low Pattern

When the needle drops to a low reading, returns to normal, and then repeats the pattern at regular intervals, you’re likely looking at a burnt, sticking, or leaking valve. Often, a sticking valve will cause more sporadic drops during this pattern.

4 or 5-Inch Fluctuation

If you notice the needle slowly fluctuating between four or five inches, chances are you have an ignition-related issue. Check your spark plug gap as this condition often indicates too narrow of a gap. Also, check your distributor cap and wires. If none of these areas are the culprit, you may need to adjust your idle mixture.

8 to 14-Inch Reading

A steady low reading between eight and 14 inches of mercury is usually indicative of incorrect valve timing.

All graphics from forums.neon.org unless otherwise noted.

Excellent information, more complete that what came with my vacuum gage. Nice work thanks

I recently spent a lot of time with a vacuum gauge while attempting yo sort the idle mixture on my ’65 Old’s 330 V8 engine.Of over 100 mixture adjustments the median vacuum was between 10 and 11 Hg but I don’t think my engine has a valve timing problem as suggested in the article.These small blocks, like other Old’s engines are known for low vacuum and my engine also has a aftermarket high lift cam so I am not concerned about these numbers.Besides the engine runs great! Bearing this in mind do you still believe I must have a valve timing issue?Regards

A larger cam in a small cubic inch motor explains the reason for a lower vacuum signal. Unless the vacuum is really jumping around on the gauge, there is no reason to suspect a valve timing issue. As mentioned the 17-22 degree reading is normal for stock cammed engines.

Needle fluctuating under accelaration i notice is one of the diagnosis, what if on idle and revved a few times, that normal? I havnt drove the pick up yet, waiting for the registration to come through.

I have been watching a lot of videos on the same thing if you take a white marker and Mark your distributor and the bottom of the distributor losing the distributor and turn it just a little bit and see if that makes a difference and if it idles up high you might have to idle it down with the idle screw but if it does not do anything you marked it so you can put it back exactly where it was but I bet it works out you should be around 17 or 18 20 is a little too high for a 350 Chevy I have even saw them as low as 15 with aftermarket cam

What does a rapid fluctuation at 16-17 in of one inch with a erratic barely visible flick down to 14 inches mean in a four cylinder ecotec 2.2 l engine?

Valve issue

“Low reading between eight and 14 inches”, turned out to be a bad spark plug or plugs in my case.

I knew without a doubt my valve timing was right, I changed the plugs just because there was no where left to go and it worked.

I have a rapid fuctuattion between 14 and 15. 327 small journal rebuilt 2000 miles ago. All new parts, car, distribution, wires spark plugs alternator, wire harness. Has mild rv cam. What could it be. I have adjusted the mix screws as best as possible. What can this be?