Summit Racing Adds New Pro LS Truck Swap and Turbo Cams to Pro LS Line (Video)

(Image/Summit Racing)

The new Summit Pro LS camshafts have been a hit.

The new product line launched in July and quickly developed a following.

Just a quick recap: Summit Pro LS cams are made in the USA and ground on a Landis 3LB for excellent lobe quality. The lobes are quick, but not so overly aggressive as to be hard on the valvetrain. Another benefit is they’re stable at high rpm to extend the horsepower curve.

The lineup was strong to begin with, but people chimed in with great ideas for new cam profiles. The result? Two new Truck Swap cams and three new Turbo grinds for non-pollution controlled vehicles.

New Summit Pro LS Truck Swap Camshafts

Since its release, the new Summit Stage 1 Pro LS Truck Swap cam has been getting great reviews. It’s a .500 lift drop-in cam with 209/217 duration, 113 lobe separation, and is ground with one degree of advance. It sounds great and tunes easy. It was designed for strong mid-range power, but owners reported something else as well.

The newfound power meant their truck no longer had to downshift going up medium grades, which helped increase their fuel economy and got Summit’s product development team thinking.

“What about all those 5.3L junkyard engines being swapped into old Winnebago RVs or trucks hauling racecars?! Let’s design a cam specifically to boost torque just off-idle, throughout the mid-range and maintain fuel efficiency.”

The result is the new Pro LS Stage 1 Drop-in Truck Swap Torque/Efficiency version.

Specs are 205/217 duration with 112 degrees of lobe separation, two degrees of advance, and .500 lift.

The new cam is designed to have a hint of an idle, won’t require a spring swap, and increases torque everywhere through the rpm range.

So how does it differ from the SUM-8712 Stage 1?

The new SUM-8718 has a slightly smoother idle and won’t require a tune—although it’s always recommended since there are power gains there as well.

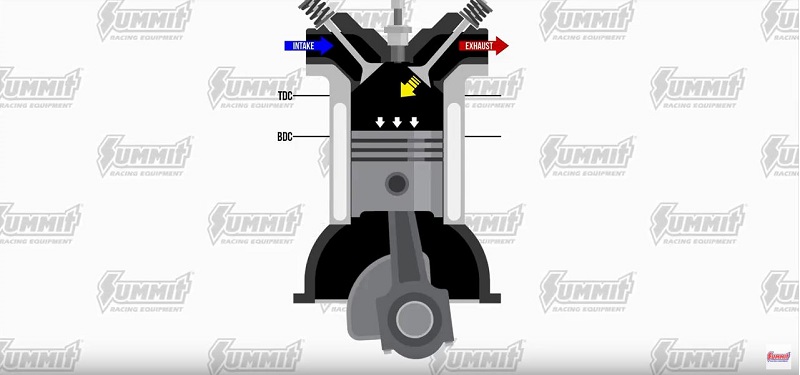

The intake valve closes three degrees earlier, which boosts low-end torque. The sooner the intake valve closes, the sooner compression can build.

Some of the Stage 1 Truck Swap cam owners also said “I love this cam… do you offer a higher lift version?” The answer is: Yes.

The new Stage 1 High-Lift Truck Swap cam has the exact same valve events as the original SUM-8712—but packs .550 lift—making it perfect for use with LS6 springs. Why LS6 springs? They’re rated for up to .570 lift and have more seat and open pressure to extend the powerband. They’re also a great value coming in around $75 and compatible with the original retainers and locks.

[table “348” not found /]…

New Summit Pro LS Turbo Camshafts

One new cam is so versatile that it could be called a number of things. A Stage 1 Automotive Stealth cam, a Stage 1 Turbo cam, or be used as a Stage 3 .600 lift Truck cam. Summit compromised and called it the Pro LS Stage 1 Stealth Turbo cam. It has 222/233 duration, 115 lobe separation, and 3 degrees of advance and has .600/.575 lift. What makes it special? The intake opens one degree after top dead center (ATDC) and closes at 43 after bottom dead center (ABDC). The exhaust opens at 55 before bottom dead center (BBDC) and closes two degrees before TDC. This results in -3 degrees of overlap. It can be tuned to run smooth or you can drop the idle for a bit of lope.

The lack of overlap also makes it an excellent turbo cam.

How were the Stage 3 and Stage 4 turbo cams developed? Summit started with the Stage 3 and Stage 4 naturally aspirated cams. Those are designed to complement the factory intake manifold design’s powerband.

What changes is the exhaust lobe and timing. The exhaust lobe is a little milder to break open easier against high cylinder pressure which takes stress off the valvetrain. The closing points are designed to net two degrees of overlap with their respective intake opening points.

Why is this important?

Single turbo engines running through a full length exhaust may exhibit high levels of backpressure between the turbo and the engine.

This is further aggravated if the wastegates are routed back through the exhaust rather than being open directly to atmosphere. The backpressure ratio could be 2:1 or even 3:1, meaning 10 pounds of boost may have as much as 30 pounds of backpressure.

This sounds bad, and it IS!

The result is exhaust trying to push back into the cylinder and intake port. By closing the exhaust valve early, Summit Turbo cams prevent reversion.

[Want to learn more about this subject? Check out How a 4-Stroke Engine’s Piston Motion and Valve Events Interact.]

The new Stage 3 Pro LS Turbo cam has 231/234 duration, 115 lobe separation and 5 degrees of advance. Lift is .600/.575, so it’s compatible with common and affordable spring packages. The exhaust valve closes at three before top dead center (BTDC).

The Pro LS Stage 4 Turbo cam has 237/234 duration, 117 lobe separation and five degrees of advance. This makes it the only reverse-split cam in the lineup. Lift is again .600/.575 and the exhaust closing point changes to five degrees before TDC.

[table “351” not found /]…

So there you have it. Summit has expanded its LS cam lineup and made it better.

The Summit Pro LS cam lineup also includes car-specific cam profiles. Here are those options and specs:

[table “350” not found /]…

To learn more about how the Summit Pro LS cams are made, read How a Camshaft is Made: A Tour of the Summit Pro LS Cams Factory.

Facebook Comments